- Change theme

Overload Relays: Types, Key Differences, Functions, and Applications

In the world of electrical engineering, overload relays are vital components safeguarding equipment from the dangers of electrical overloads.

01:04 27 December 2024

In the world of electrical engineering, overload relays are vital components safeguarding equipment from the dangers of electrical overloads, ensuring safety and efficiency. From industrial giants to small businesses, overload relays find their place in numerous applications, making them indispensable across various fields.

What Are Overload Relays?

Overload relays are protective devices used in electrical circuits to prevent motors and other equipment from overheating due to excessive current. They act as a safeguard, interrupting the circuit when the current exceeds a pre-set level, thus protecting against potential damage. Overload relays are crucial in maintaining the longevity and performance of electrical systems in industrial and commercial environments. They function as a bridge between the motor and the power supply, monitoring the current flow and taking action when necessary.

There are different types of overload relays, each with unique features and functionalities. Understanding the basic principles of overload relays is essential for choosing the right one for your application. These devices work by detecting excessive heat generated by the current flow. When the temperature reaches a certain threshold, the relay activates, breaking the circuit and preventing further damage. They are typically used in conjunction with contactors, providing a complete solution for motor control and protection.

By incorporating overload relays into your electrical systems, you can ensure operational efficiency and protect valuable equipment from costly damage. They serve as an insurance policy for your electrical infrastructure, reducing downtime and maintenance costs while enhancing overall safety.

Exploring Different Overload Relay Types

In electrical engineering, selecting the appropriate overload relay is essential for ensuring reliable motor protection and preventing equipment damage due to excessive current. Each type of relay operates based on different principles and is suited to specific operational requirements, offering distinct advantages for various applications.

- Thermal Overload Relay

Thermal overload relays operate on the principle of heat generation by electrical current. They utilize a bimetallic strip, which consists of two metals with different coefficients of thermal expansion. When current flows through the relay, the bimetallic strip heats up and bends due to the differential expansion of the two metals. Upon reaching a predefined bending threshold, it triggers a mechanical mechanism to open the circuit, thereby disconnecting the power supply to the motor.

Advantages:

- Simplicity and Cost-Effectiveness: Thermal overload relays are relatively straightforward in design, making them easy to install and maintain. Their mechanical nature makes them a cost-effective solution for motor protection in many standard industrial applications.

- Reliable for Gradual Overloads: They are well-suited for applications where the current increases gradually, allowing the relay to detect the proportional rise in heat and react accordingly. This makes them ideal for applications with consistent operational loads and minimal temperature fluctuations.

Limitations:

- Slower Response Time: Because thermal relays rely on the generation of heat to operate, they can be slower to respond to sudden, short-term current spikes. This could allow brief, potentially damaging overloads to pass through undetected.

- Environmental Sensitivity: The performance of thermal overload relays can be affected by ambient temperature changes, which may alter the activation point. This makes them less suitable for environments where temperature conditions vary significantly.

Applications: Thermal overload relays are typically used in applications with steady-state operations, such as fans, pumps, and conveyors, where the motor load does not experience frequent or extreme variations. They are also commonly integrated into simple motor starters due to their easy-to-use nature.

- Electronic Overload Relay

Electronic overload relays employ solid-state circuitry to continuously monitor the current flowing through the motor. Unlike thermal relays, which depend on physical bending mechanisms, electronic relays utilize sensors and microcontrollers to analyze the current and detect any deviations from preset levels. This allows them to offer precise, adjustable, and real-time motor protection.

Advantages:

- Enhanced Precision and Sensitivity: Electronic relays can accurately detect even small deviations from the nominal current, providing precise overload protection. This makes them suitable for sensitive equipment where maintaining optimal performance is crucial.

- Adjustable Settings and Advanced Features: These relays often come with adjustable trip settings, allowing engineers to fine-tune the protection parameters based on specific application requirements. Additional features such as phase-loss protection, ground fault detection, and real-time current monitoring ensure comprehensive motor protection.

- Resilience to Environmental Variations: Unlike thermal relays, electronic overload relays are less impacted by changes in ambient temperature. This ensures consistent performance, even in environments subject to temperature swings.

Limitations:

- Higher Complexity and Cost: Electronic relays are more complex than their thermal counterparts, requiring a greater level of expertise for installation and maintenance. Their advanced features also make them more expensive, which can be a consideration for budget-constrained projects.

- Power Supply Dependency: Since electronic relays rely on electronic components, they require a reliable power source to function. In scenarios where power reliability is a concern, this could be a potential drawback.

Applications: Electronic overload relays are ideal for applications where accurate and fast response to current fluctuations is necessary. They are used extensively in scenarios that involve variable loads, such as elevators, HVAC systems, and process control applications, where real-time monitoring and precise overload protection are critical.

Choosing the Right Overload Relay

Selecting the appropriate overload relay for your application involves considering several key factors. By evaluating these elements, you can ensure optimal protection and performance for your electrical systems.

- Rated Current

The rated current of an overload relay is the maximum current it can handle without tripping. It's crucial to choose a relay with a rated current that matches the requirements of your application. A relay with too low a rating may trip unnecessarily, while one with too high a rating may fail to provide adequate protection.

Consider the current draw of your equipment under normal operating conditions, as well as any potential fluctuations or surges. This will help you select a relay with the appropriate rated current, ensuring reliable performance and protection.

- Load Type

Different overload relays are designed to handle specific load types, such as resistive, inductive, or capacitive loads. It's essential to choose a relay that can accommodate the unique characteristics of your load, as this will impact its performance and reliability.

For example, an inductive load, such as a motor, may require a relay with a higher rated current and specific features to handle the inrush current during startup. Understanding the load type and its requirements will guide you in selecting the most suitable relay for your application.

- Working Environment

The environment in which an overload relay operates can significantly impact its performance and longevity. Factors such as temperature, humidity, and exposure to dust or chemicals can affect the relay's functionality, making it essential to choose a relay suited to the specific conditions of your application.

Consider the environmental conditions your relay will be exposed to and select one with the appropriate protection features. This may include sealed enclosures, corrosion-resistant materials, or temperature compensation capabilities, ensuring reliable performance in challenging environments.

Introducing CHINT’s Overload Relays

CHINT offers a range of overload relays designed to meet the diverse needs of modern electrical systems. Each series provides unique features and benefits, catering to various applications and environments.

The NR2 series offers thermal overload protection using a bimetallic strip mechanism. It features auto/manual reset modes, phase failure protection, and auxiliary contacts, making it suitable for a broad range of motor current protection applications.

With its simple design and reliable performance, the NR2 series is an excellent choice for applications where gradual overloads are a concern. Its wide application range and ease of use make it a versatile option for many industries.

The NRE8 series provides electronic overload protection with LED indicators, a wide adjustment range, and multi-function protection capabilities. It offers accurate overload detection and additional protection features, such as short-circuit and phase imbalance protection.

The advanced features of the NRE8 series make it ideal for applications requiring precise current monitoring and enhanced protection. Its user-friendly design and comprehensive protection capabilities provide peace of mind for electrical systems of all sizes.

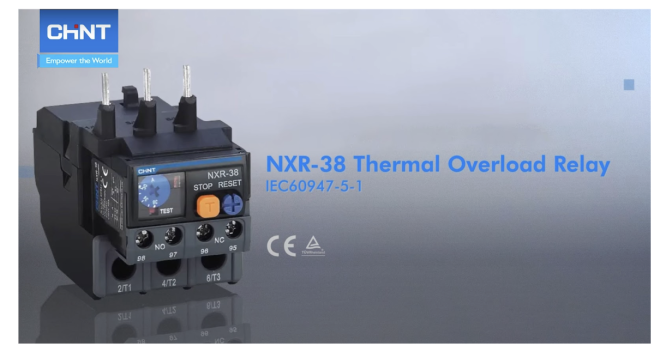

The NXR series offers overload protection tailored to different motor sizes. Smaller models in the series utilize thermal overload protection, which is ideal for smaller motors and simpler applications. For larger motors, the NXR series employs electronic overload protection, providing greater precision and enhanced features. This distinction allows for optimal performance across a wide range of motor sizes.

The modular design of the NXR series facilitates easy expansion and customization, making it a versatile solution for complex electrical systems. With its combination of thermal protection for smaller motors and electronic protection for larger ones, the NXR series ensures reliable performance and safety in demanding environments.

Conclusion

Overload relays play a vital role in protecting electrical systems from the dangers of excessive current. By understanding the different types, functions, and applications of overload relays, you can make informed decisions that enhance the safety and efficiency of your systems.

CHINT's range of overload relays offers diverse solutions tailored to meet the needs of modern electrical systems. From thermal to electronic protection, their innovative designs and advanced features provide comprehensive protection for a wide range of applications.

For electrical professionals seeking reliable and efficient overload protection, understanding the options available and choosing the right relay is crucial. By doing so, you can ensure the longevity and performance of your equipment, safeguarding your investments and maintaining operational excellence.