- Change theme

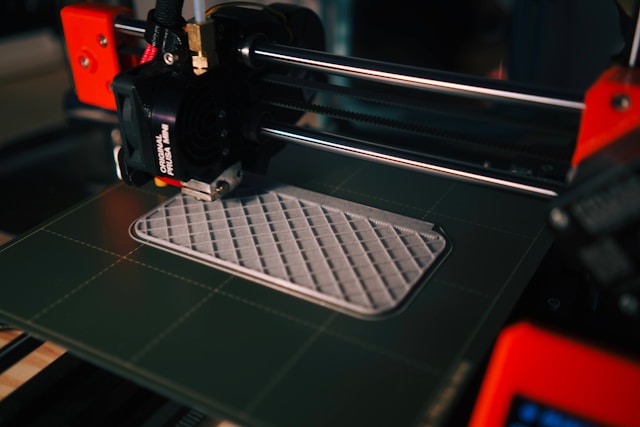

5 Advantages of SLA 3D Printing in Manufacturing Technology

Stereolithography (SLA) 3D printing has gained significant popularity in the manufacturing industry due to its precision, versatility, and efficiency.

05:46 26 February 2025

Stereolithography (SLA) 3D printing has gained significant popularity in the manufacturing industry due to its precision, versatility, and efficiency. This technology utilizes a UV laser to solidify liquid resin layer by layer, creating high-quality, detailed prototypes and functional parts. Below are five key advantages of SLA 3D printing in manufacturing technology.

Exceptional Precision and Detail

One of the standout benefits of SLA 3D printing is its superior precision. The technology allows for the production of intricate parts with tight dimensional tolerances for the first inch. The laser-curing process ensures that each layer is solidified accurately, making it ideal for industries requiring fine details, such as medical devices, jewelry, and aerospace components.

SLA printers can deposit thin resin layers, producing smooth surface finishes and reducing the need for extensive post-processing. This level of accuracy is often unmatched by other 3D printing technologies, making SLA a preferred choice for high-precision applications.

Versatile Material Options

SLA 3D printing supports a broad range of resins, allowing manufacturers to choose materials based on their specific needs. These resins include standard resins, ideal for general-purpose applications with high detail and smooth finishes, and transparent resins used for optical clarity in light transmission and inspection applications. Others are flexible resins designed for components that require elasticity and resilience and high-temperature resins suitable for applications that must withstand extreme heat conditions. This variety enables manufacturers to produce functional parts with properties that match their intended use, from rigid industrial components to flexible prototypes.

Minimal Printing Errors and High Repeatability

Unlike traditional 3D printing technologies that use thermal expansion, SLA utilizes a UV laser to harden liquid resin. This eliminates thermal distortions and ensures high repeatability in production. The precise calibration of the laser reduces warping and structural inconsistencies, making SLA an excellent choice for producing highly complex geometries with consistent quality.

SLA’s minimal printing errors make it particularly beneficial for sectors such as healthcare, automotive, and consumer electronics, where accuracy is critical. Manufacturers can rely on SLA to produce detailed parts without worrying about inconsistencies between batches.

Fast Production and Efficient Post-Processing

SLA is often perceived as slower than other 3D printing technologies, but it offers rapid turnaround times for high-detail models. A fully functional part can be printed in as little as 24 hours, depending on its complexity. This makes SLA particularly valuable for rapid prototyping, where quick iterations are needed to refine designs before mass production.

Additionally, SLA’s post-processing is relatively simple. The printed parts have inherently smooth surfaces, reducing the need for extensive sanding or polishing. If further refinements are needed, manufacturers can easily paint or polish SLA-printed parts without excessive effort. This efficiency streamlines the workflow and reduces production lead times.

Cost-Effective for Prototyping and Small Production Runs

For manufacturers looking to develop prototypes or limited production runs, SLA offers a cost-effective solution. Unlike traditional manufacturing methods that require expensive molds and tooling, SLA prints directly from a CAD file, significantly lowering production costs.

Startups and small businesses benefit from SLA’s affordability, as they can produce market-ready products without significant upfront investment. Moreover, the ability to iterate designs quickly without incurring additional mold costs makes SLA an attractive option for product development and refinement.

In conclusion…

SLA 3D printing continues to be a game-changer in manufacturing technology, offering unparalleled precision, material versatility, minimal errors, fast production, and cost-effective prototyping. Its ability to create highly detailed parts with smooth finishes makes it an invaluable tool for industries that require accuracy and efficiency. As 3D printing technology evolves, SLA remains a leading choice for manufacturers seeking high-quality production without compromising on detail or consistency.